Hello,

You have no worries... both of your ballasts are hot cathode types... I would have warned you if you were running into problems, or taking any risks (i.e. DON'T DO IT!! etc.).

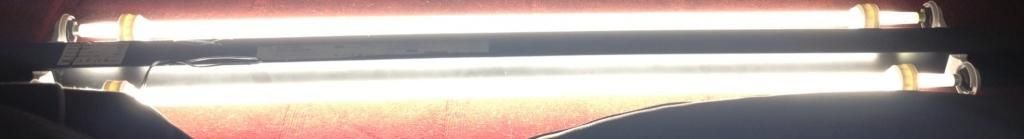

FYI. A fluorescent tube (more properly called a fluorescent bulb... I prefer "tube") has two small heating elements at each end of the tube (often called filaments). These are electrically isolated from each other and are connected to the pins on the tube ends.

A hot cathode ballast works in the following way:

Power is applied to the heaters, which start to glow (this is where the name "preheat" comes from). The heaters start to emit electrons (in the same way as a 1920's "bright emitter" radio valve). A voltage is applied across the tube (from end to end), this voltage forces the electrons to travel from one end of the tube to the other.... The tube has "struck" or started...

A cold cathode ballast works slightly differently.

The heaters are not preheated. A high voltage pulse is applied across the tube ends.. This high voltage pulse forces electrons to be emitted, which are attracted from one end of the tube to the other. The tube has "struck" or started.. The heaters do glow... but this is due to electron flow in the tube... not to any heater pin to pin circuit. This is how a cold cathode ballast can work with only one connection per tube end.

Now, what happens in the tube is the same with both types of ballast. The tube contains a small amount of mercury (to help with this process) and a mixture of gases at low pressure. Moving electrons impact gas and mercury atoms.. causing them to ionise (the atoms "take up" energy, an "excited" energy state.). This energy is released in the form of UV light. This UV is converted to visible light by the phosphor coating placed on the inside wall of the tube. The exact chemical makeup of this coating dictates the colour spectrum of light emitted.

Now the ballast "running" output is AC. Electronic ballasts run at high frequency. This is why you don't see the traditional 50Hz (cycles per second) or 60Hz (US mains frequency) flicker that you can get with traditional magnetic ballasts. Some people are very sensitive to this.. I am. Some shops/stores have lighting powered by really cr@&&y ballasts.. the flicker often makes me feel ill!

The main job of the ballast is this. As the tube begins to emit light, the resistance of the ionised gas mix begins to decrease... This would otherwise mean that the current flow in the tube would increase... a "runaway" effect. The ballast limits the current flow to a safe level. Too high a current flow and the tube would be destroyed.

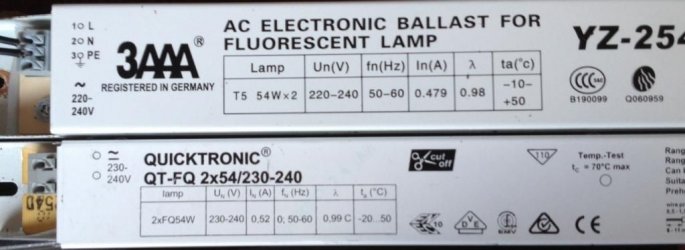

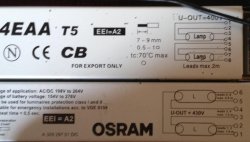

This is one of the main reasons that the ballast has to be matched to the tube size and power rating..

Further advantages of electronic ballasts are:

Lower overall power consumption and running costs (more efficient).

Monitoring of tube operating conditions. (automatic switchoff if any "out of spec" conditions detected). This is often the cause of peoples puzzlement when their lights either don't switch on at all or switch themselves off after a short time.

EOL (end of [tube] life) detection. A failing (ageing or "worn out") tube can overheat... This, with a magnetic ballast, can melt the tube sockets or even the tube glass. It is potentially a fire risk. Tube sockets should be made from "self extinguishing" materials... some are not!). The ballast will refuse to strike under these conditions.

One last thing... The reason why you see many more hot cathode ballasts for sale than cold cathode types is because magnetic ballast systems are, by definition, 4 wires per tube circuits....

Replacement or upgrades therefore are often hot cathode types. This makes replacement easier to do... No "spare" wires to worry about!

You will also come across various hybrid types. Some of these are truely horrible "things"!

See, I told you that I was "full of it"!

Regards,

Bob (aka Bodge99).

/item.mobileweb.ebay.co.uk/viewitem?itemId=250807834612

/item.mobileweb.ebay.co.uk/viewitem?itemId=250807834612