HappyGeorge

Fish Herder

So I finally have the time to get started on my project.

This is my first ever tank and I want to take my time and make a decent job of it.

The equipment is a Rena Aqualife 450 aquarium with a Fluval FX5 and a U4 and 2 x 200w heaters.

The plan is to keep Malawis and to focus on algae eaters and to go for medium aggression specimens I have no plans to run any breeding at the moment but will let nature take its course in the tank.

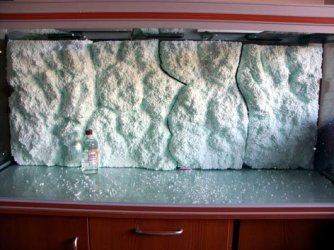

I originally bought 3 x juwel rock 3D backdrops for this tank but I didn't like the way they joined together or the fact that I would have to cut them to get them in. This is because the Rena has bracing pieces that dont have the clearance to get the juwel pieces in.......my first newbie error.

As you will see from the photo I have had it since before Christmas and the tank is clearly used (ex-display) but it is now clean and ready for action.

The plan is to have a lot of rock work in there and rather than eggcrate I am planning on using the stuff you can see in the bottom left hand corner of the photo which is shock absorbant matting designed for use in machine workshops. A nice alternative as it is nice and thin easily cut to size and cheap at £12 for enough for the whole tank.

This is my first ever tank and I want to take my time and make a decent job of it.

The equipment is a Rena Aqualife 450 aquarium with a Fluval FX5 and a U4 and 2 x 200w heaters.

The plan is to keep Malawis and to focus on algae eaters and to go for medium aggression specimens I have no plans to run any breeding at the moment but will let nature take its course in the tank.

I originally bought 3 x juwel rock 3D backdrops for this tank but I didn't like the way they joined together or the fact that I would have to cut them to get them in. This is because the Rena has bracing pieces that dont have the clearance to get the juwel pieces in.......my first newbie error.

As you will see from the photo I have had it since before Christmas and the tank is clearly used (ex-display) but it is now clean and ready for action.

The plan is to have a lot of rock work in there and rather than eggcrate I am planning on using the stuff you can see in the bottom left hand corner of the photo which is shock absorbant matting designed for use in machine workshops. A nice alternative as it is nice and thin easily cut to size and cheap at £12 for enough for the whole tank.

Probably saved yourself a small fortune against the commercial ones available and it looks just as good.

Probably saved yourself a small fortune against the commercial ones available and it looks just as good.