kiko

Fishaholic

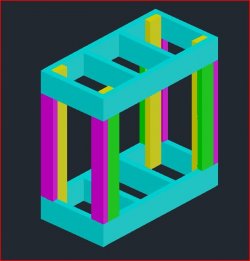

have you tried to bend a .100 thickness sheet? it takes a forklift or 3 men to bend a single 48x96 sheet...squared tubing is wayyyy stronger than a flat sheet...Looking closer, it could work, depending on the loads, if the back of the center section was covered with a panel, which would save weight and cost.

you can literally grab 2 tubes and it would hold a car which averages 3-4 thousand pounds on it easy much less 2 fish tanks which at 45galx2 is around 750pounds