I've been wondering if this sort of setup could work (not that I'm thinking of getting two more tanks, oh no  )

)

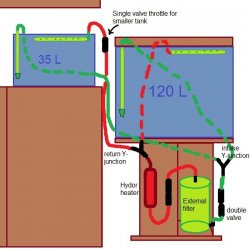

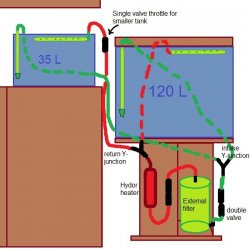

Two tanks, 35 and 120L

External filter, e.g. Eheim

External Hydor heater

Two Y junctions on the intake and return pipes to run both tanks through one filter

Single valve on return pipe to small tank to throttle flow (if necessary)

Could this work and what are the potential problems of doing it?

Click on diagram to see what I mean

Two tanks, 35 and 120L

External filter, e.g. Eheim

External Hydor heater

Two Y junctions on the intake and return pipes to run both tanks through one filter

Single valve on return pipe to small tank to throttle flow (if necessary)

Could this work and what are the potential problems of doing it?

Click on diagram to see what I mean