Buddy !!!

That's "Hard core" !!!

The particleboard sides are attached with cam locks, I followed the instructions that came with that terrible stand and didn't use any glue.

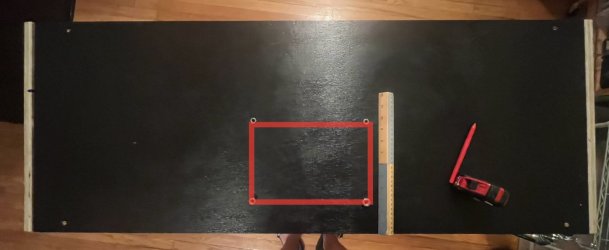

I have completed most of the new stand and used wood glue and deck screws to create the 2x4 frame and attach the exterior plywood sides. Now I have to make and attach plywood cutouts to the front for the doors. I am going to attempt to create and design ADA-style doors for it with piano hinges. However, the frame has a small gap between 2 of the legs and the plywood top. These 2 legs are both on the same side and there are 6 more that are flush with the plywood top. 2 other legs are flush with the top on the same side and all 4 on the other side are flush with it also. Would this be a problem?

Also, I should be finished with it by the end of this week. As requested I will send pictures when done

That's "Hard core" !!!