For those remotely interested here is the DIY self build tank stand info which I have coloured up for ease of use. This stand is far stronger than any tank manufacturers stand because it is MDF and not chipboard MFC that the big manufacturer uses. Also, the joints are dowelled and not cam / pre-drill jointed which is also more robust.

Of course you can bespoke these board dimensions to suit your tank - I think any tank larger than 120 cm wide or more weight than 120 litre would need at least 1 centre post on the front. It's all to do with how crazy and/or lucky you feel I guess. On the Rekord 80 I feel crazy and lucky so have relied on the end/back panels to keep things vertical. MDF is a very strong board, when dry, so you may get away with more than I recommend

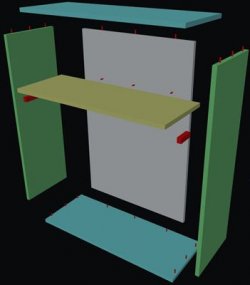

Exploded CAD diagram for reference

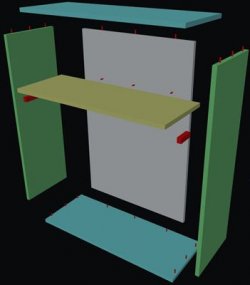

Exploded CAD diagram for reference

In the above image:

Blue: 2 number 800 x 300 x 18mm MDF - (Top and bottom)

Green: 2 number 900 x 300 x 18mm MDF - (Left and Right)

White: 1 number 900 x 600 x 18mm MDF - (Back)

Yellow: 1 number 764 x 280 x 18 mm MDF - (Shelf)

Red: Round things - 6 x 40mm dowels

Red: Square things - 40 x 50 x 18mm MDF offcut shelf supports

I ripped all the boards down to suit the sizes above. Dry assembled whole thing using gaffer tape on the bench. This allowed me to place pencil marks on the internal corners between internal board joint corners where I would like to place a dowel joint. No measurement was used, just this: stick in a pencil mark on each board per dowel hole that you want. I then ripped the dry fit apart, eyeballed and marked the drill positions then got busy with Mr Bosch drill @ 6mm (which is the bore of the dowel) at every required dowel point. Then glued dowels into top / bottom board with quick dry PVA (the EVOstick one)

2nd dry fit after the dowels were dry (actually getting dowels into dowel holes) and it all went together well after a tap from Mr Tapometer (hammer). I was crapping this stage as if my eyeballing of dowel drilling was not good, the whole build would be ruined. However it was all good

and I believe yours will be too if enough care / time is taken.

Final fit involved tapping and glueing the whole shebang together and glueing the shelf blocks in place.

After 1 hour (quick dry PVA watchout!) I manhandled the new cabinet into it's resting position in the kitchen, whacked on the tank and filled it so that I could get pressure down through onto the curing glue joints.

My whole build took 4 hours but I do faff up and down making sure things are precise - an experienced builder would have this nailed in 1 hour I guess.

Jobs a good un, next step is to paint the cabinet.

with signed authorisation sought from Wife

with signed authorisation sought from Wife