Looks pretty flimsy to me...

Might hold a 5 gallon... just dont use any stone.

EDIT: alright alright, i decided id stop being a wise ass and show you my current work in progress.

72G Bowfront, Drilled.

Yes, its upside down that's just how i had left it

That sump is only half the situation, theres a refugium to match just not in photo but this isn't about that.

That ONE rectangular hole was enough reason to get the misses to let me get a new dewalt jigsaw! huzzah!

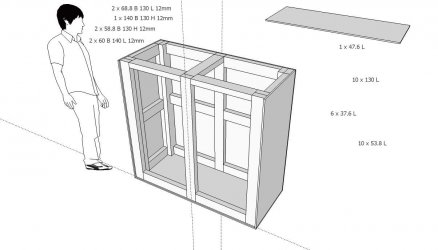

Alright on to the stand itself.

Everything is in 2x4 using those magnificent steel hangers / braces. made putting it together a breeze.

The only problem with these hangers was the screw heads, they stick out and make it so that you cannot mount anything flush to the front. And since i have all 3/4ths inch solid oak going on i had to remedy the situation. Using simple spacers over the screw areas to mount the panels on.

These show some interior bracing which ill actually be using to mount various lights for the refugium and even a drawer for some things. If i think on it too long soon ill add a coffee maker, jet engine, and flux capacitor.

Originally to mount the top i was going to use camber lock / pins for keeping the top in place but then i did the math for the weight that will actually be on and well. lol. just the pins will suffice. There are 5 pins total these are the pins that came with the camber locks but the extra many many hours of work needed to properly drill the holes for the turn keys would be totally unnecessary.

And last but not least the overflow hole. Some of you may have been standing there scratching your heads wondering why i cut that section of 2x4 out of the back and did all the extra bracing work. well, i wanted a 2 inch "lip" if you will around the whole tank so that i could use some edging or whatever i choose to hide the foam sheet the tank will be sitting on. But either way, the bulkheads JUST clear the piece of 2x4 but the union valves i have attached to those, wont fit, so away it went! now i have PLENTY of workable space.

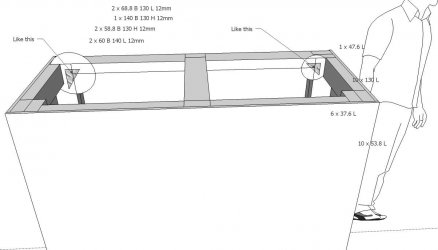

The design you chose is even more over engineered than mine. It will work out just fine mate. Just take your time flush everything and you should be set, and remember screws, never nails.

-Chairman Wood

/www.byoswingset.com/smaltrianbra.html"]http

/www.byoswingset.com/smaltrianbra.html"]http